Automated CAD-to-Simulation Workflow

Highlights

Prepare complex CAD models for simulation analysis—an extensive manual process that bottlenecked the design optimization cycle.

Built an automated workflow that programmatically defeatures complex CAD models and validates geometry for simulation-ready export.

File preparation reduced from 10 hours to under 1 second, accelerating the design optimization cycle by orders of magnitude.

Background

Design optimization for defense applications requires running thousands of simulation analyses to evaluate structural, thermal, and impact performance across the design space. Each simulation requires a clean, simplified version of the CAD model—small features, fillets, and manufacturing artifacts that are irrelevant to the physics must be removed before the model can be meshed and analyzed.

The Challenge

Preparing complex CAD models for simulation was an entirely manual process. An engineer would spend approximately 10 hours per model removing small features, healing geometry issues, simplifying assemblies, and validating that the resulting model was suitable for meshing. With optimization cycles requiring hundreds or thousands of simulation runs, this manual preparation step was the primary bottleneck—limiting the number of design variants that could be evaluated and slowing the path to validated solutions.

Our Approach

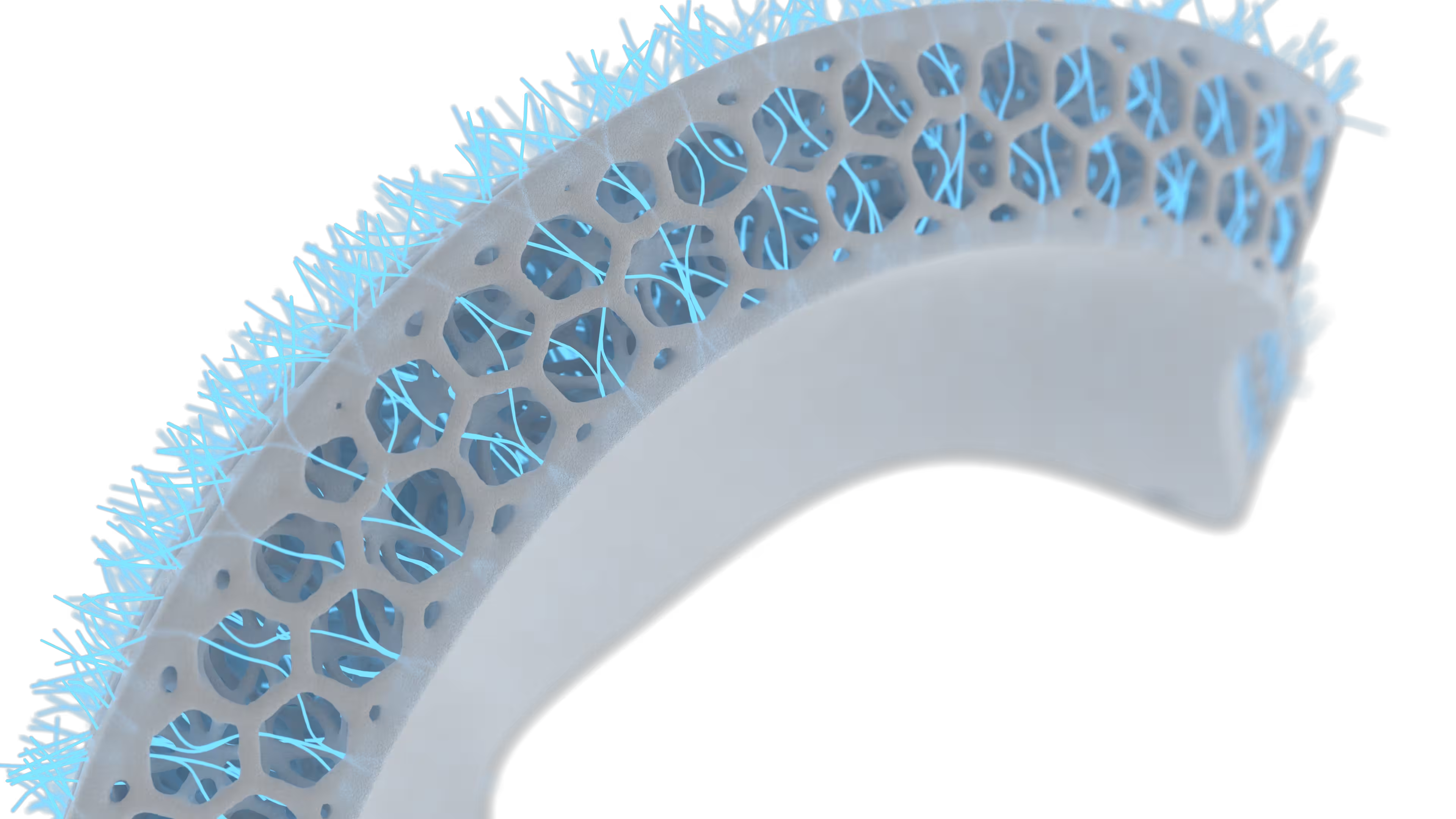

General Lattice built an automated workflow that programmatically analyzes complex CAD geometry, identifies features that should be removed for simulation purposes, defeatures the model according to configurable rules, repairs geometry issues, and validates that the resulting model meets meshing requirements. The workflow was designed to handle the specific complexity patterns found in defense hardware—multi-body assemblies, lattice structures, and tight-tolerance interfaces.

The Outcome

The automated workflow reduced simulation file preparation from 10 hours of manual engineering work to under 1 second of automated processing. This acceleration removed the preparation bottleneck entirely, enabling full design space exploration for the first time. Engineers could now evaluate thousands of design variants rather than the handful that manual preparation allowed, leading to better-optimized solutions delivered faster.

The workflow has been integrated into General Lattice's design optimization pipeline, where it continues to accelerate development cycles across multiple defense programs.

Ready to start a project?

Tell us about your requirements and we'll explore how GL Defense can help.

Contact Our Defense Team