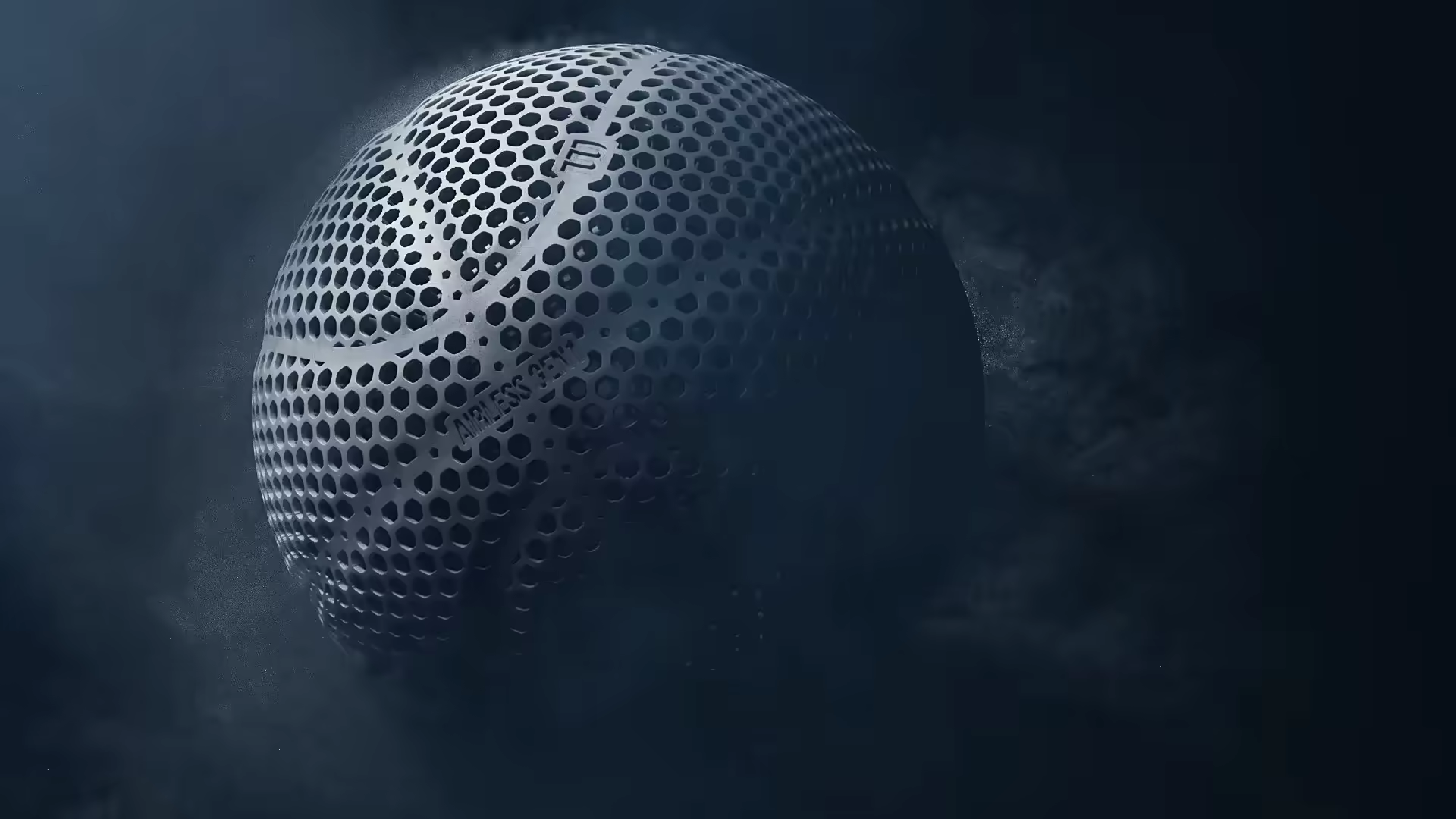

Wilson Airless Basketball

Highlights

Develop an airless basketball that matched the performance specs of a traditional game ball—size, mass, and rebound.

Developed a multi-objective parametric model to explore complex lattice geometries, optimizing for traditional game ball performance.

A 3D printed airless basketball that matched performance specs. Solved in 3 months—a challenge Wilson had been working on for 4 years.

Background

Wilson Sporting Goods, one of the world's leading manufacturers of sporting equipment, had been exploring airless basketball concepts for over four years. The challenge was fundamental: how do you replicate the bounce, weight, and feel of a traditional air-filled basketball without the air? Previous attempts using conventional engineering approaches had failed to match the performance characteristics that players expect.

The Challenge

An airless basketball must match the performance specifications of a traditional game ball across multiple dimensions simultaneously—size, mass, rebound height, and feel. These requirements are interdependent: changing the geometry to improve bounce affects weight, and optimizing for weight changes the structural response. Traditional design methods force engineers to optimize one parameter at a time, leading to compromises that fall short of game-ball performance.

Our Approach

General Lattice developed a multi-objective parametric model that could explore thousands of complex lattice geometries in parallel. Rather than iterating on a single design, we encoded the design logic into a computational framework that simultaneously optimized across all performance targets. The parametric model allowed us to systematically explore the relationship between lattice geometry, material distribution, and structural response—finding solutions in a design space too large for manual exploration.

The Outcome

In three months, General Lattice delivered a 3D printed airless basketball that matched the performance specifications of a traditional game ball. The design was validated through physical testing against Wilson's performance benchmarks, demonstrating that computational design can solve complex multi-physics problems that resist conventional approaches.

The project demonstrated a core principle of the General Lattice approach: when performance is controlled by geometry rather than locked in by material chemistry, the design space opens up dramatically—and computational methods can navigate that space far faster than manual iteration.

Ready to start a project?

We'd love to hear about your project and explore how we can help.

Talk to Our Team