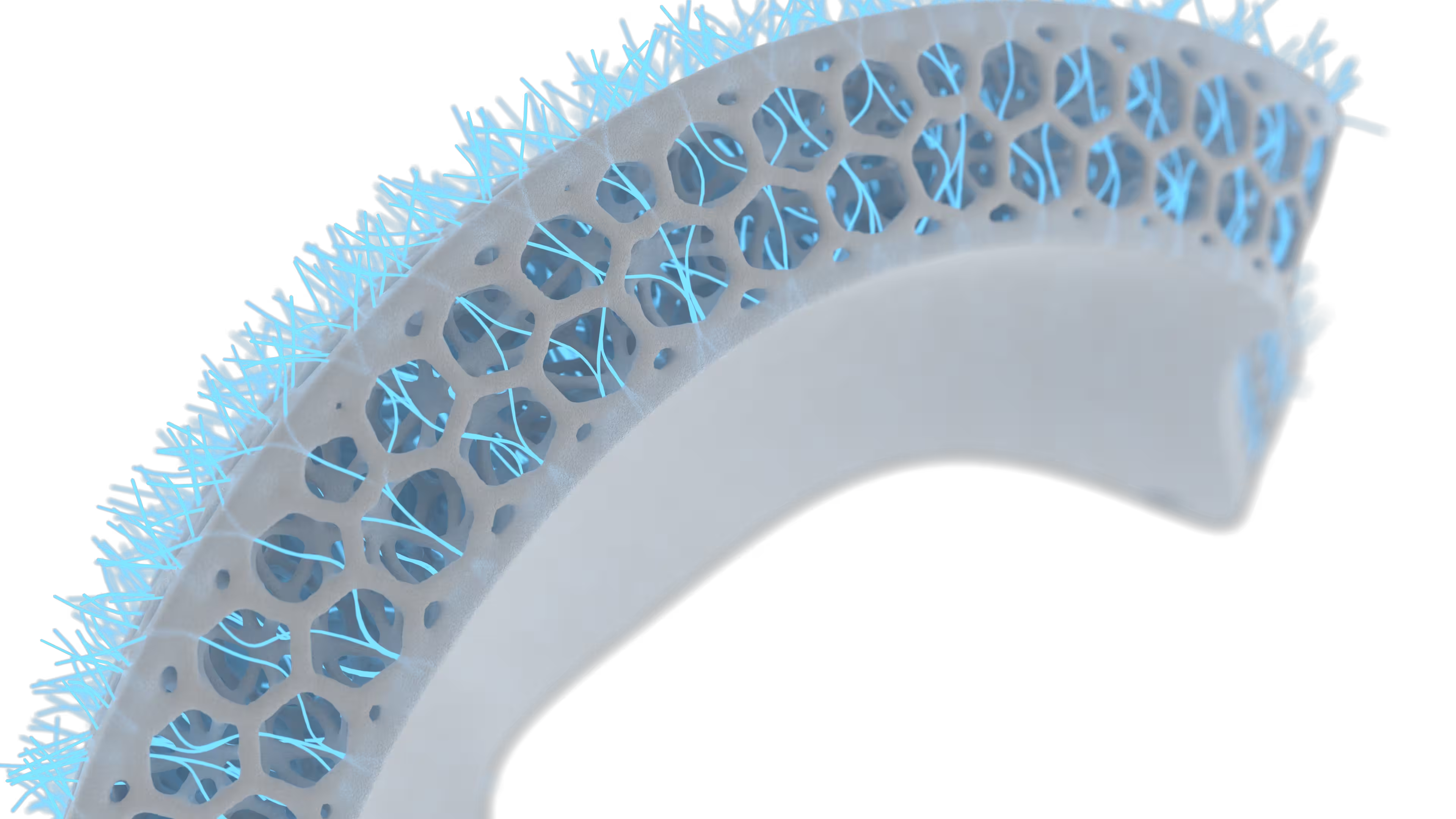

Computational Design + Digital Manufacturing

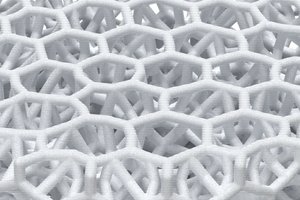

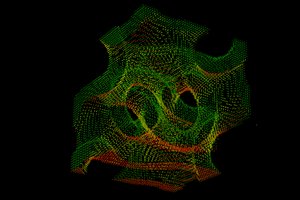

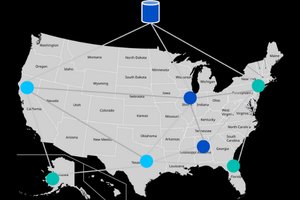

We eliminate those constraints through an integrated approach. Computational design explores entire solution spaces in parallel, optimizes across all objectives simultaneously, and regenerates variants in days when requirements change. Digital manufacturing enables distributed, on-demand production without tooling constraints.