Projects We've Delivered

From novel challenges to production-ready solutions. Each project demonstrates what's possible when computational design meets real-world requirements.

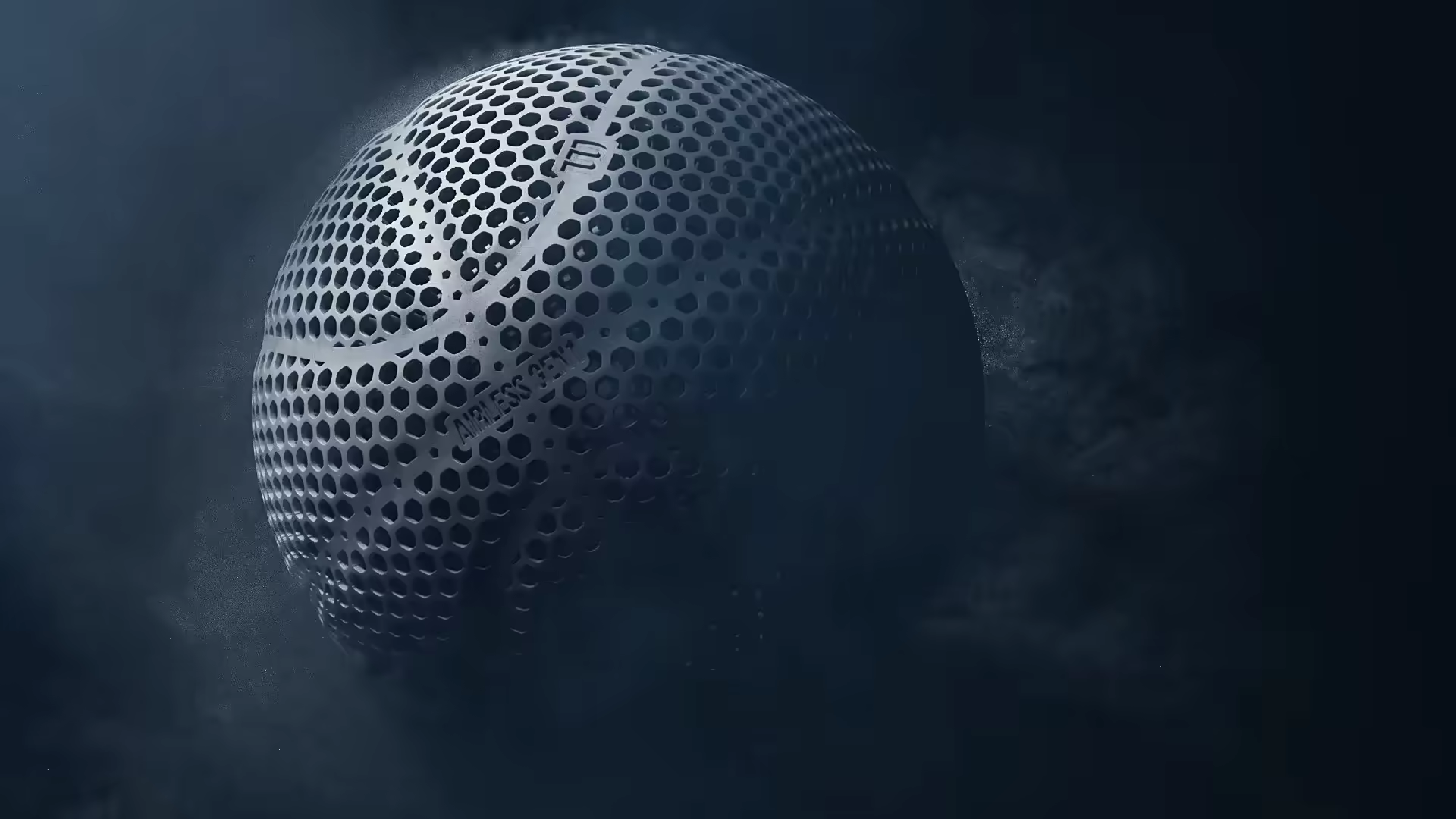

Wilson Airless Basketball

Develop an airless basketball that matched the performance specs of a traditional game ball—size, mass, and rebound.

Developed a multi-objective parametric model to explore complex lattice geometries, optimizing for traditional game ball performance.

A 3D printed airless basketball that matched performance specs. Solved in 3 months—a challenge Wilson had been working on for 4 years.

Mak Studio Wall Installation

Automate the design-to-manufacturing process for hundreds of uniquely shaped wood pieces—each requiring its own manufacturing file.

Built an intelligent design-to-manufacturing pipeline that converted unique design profiles into production-ready DXF files.

Over 900 unique manufacturing files generated in less than 1 second—a process that originally took approximately 3 months.