Trusted by leaders in demanding industries

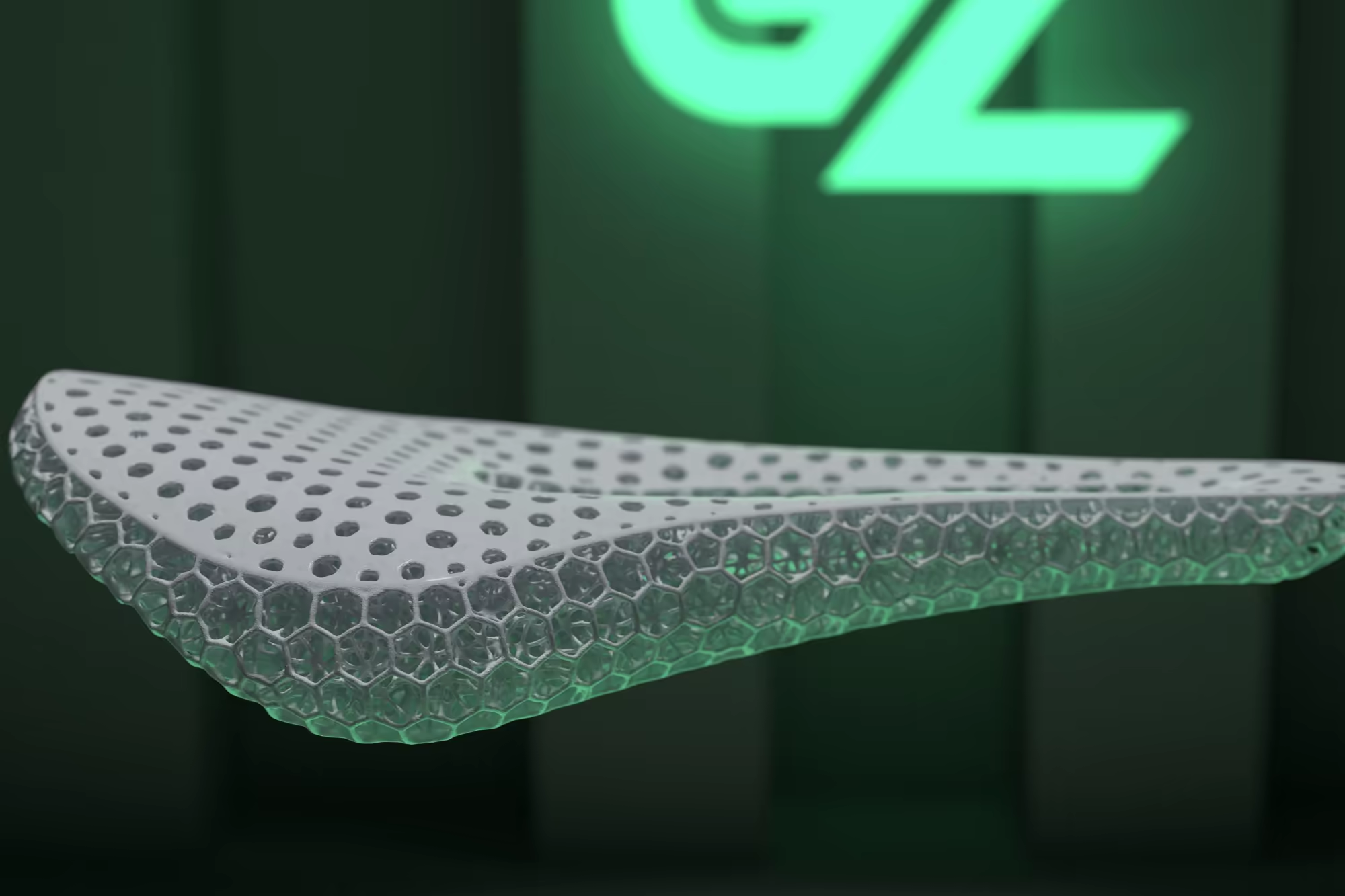

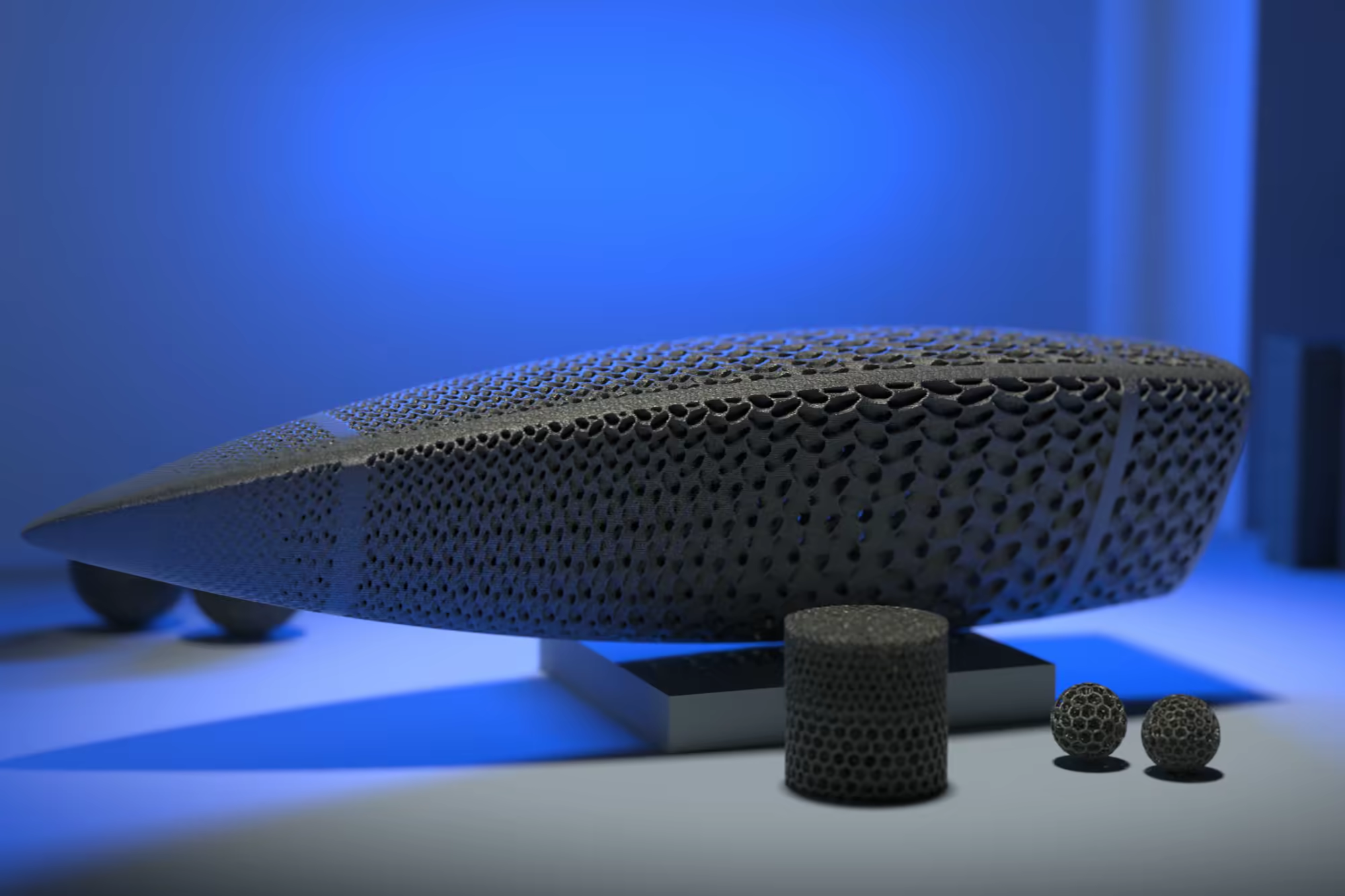

We work with customers to develop advanced products and technologies using computational design and digital manufacturing to move faster, reduce risk, and improve performance.

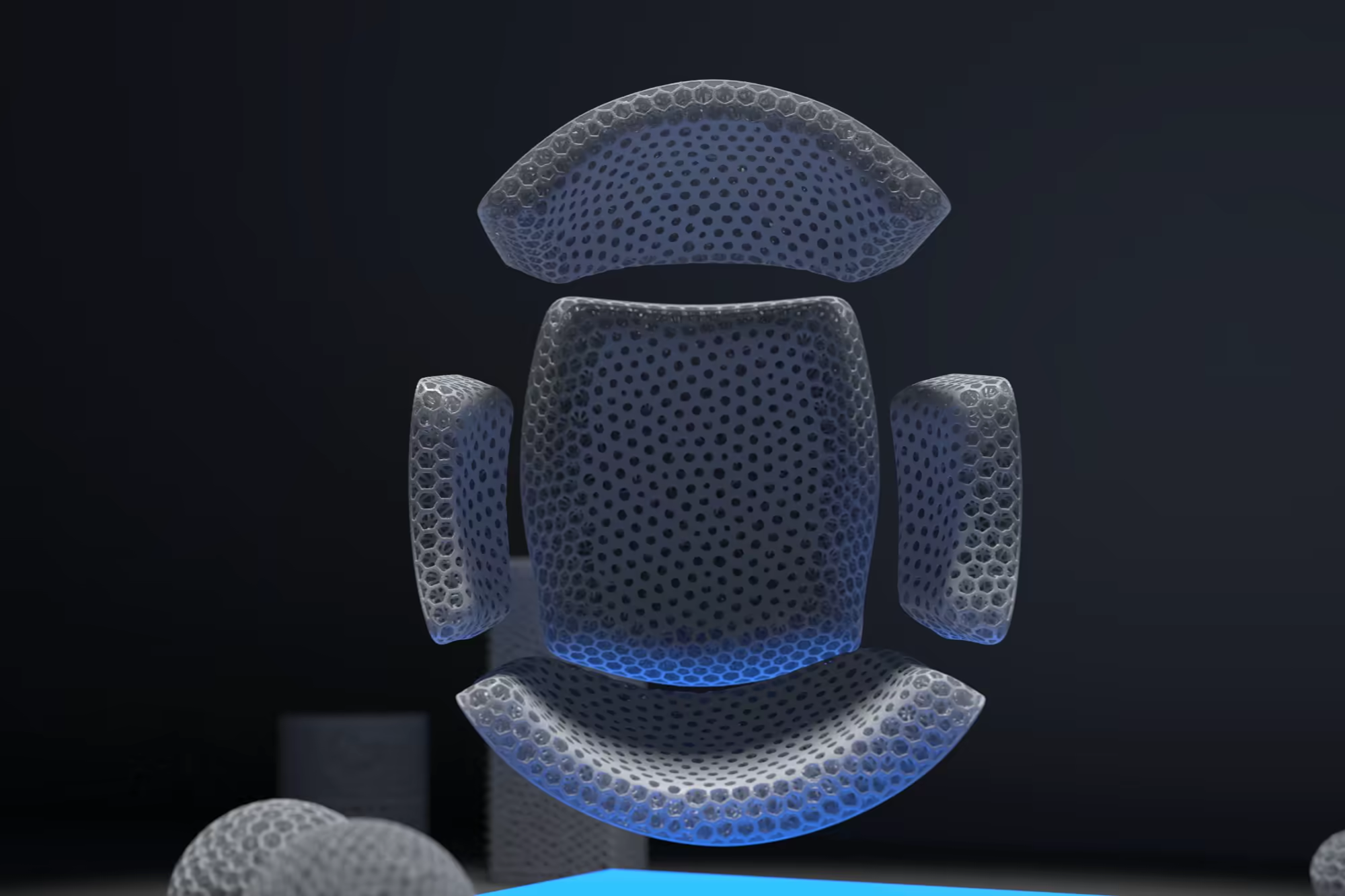

Build without compromise

Verticals

Explore our system portfolios, each configurable to your specs, requirements, and manufacturing constraints.

Services

We partner with commercial and federal customers to design and manufacture custom high-performance systems, from concept through production. If your requirements push beyond what off-the-shelf solutions can address, we'll engineer it.